Magnetic Flux Leakage [MFL]

Magnetic Flux Leakage -in short MFL- is a method of Non-Destructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks.

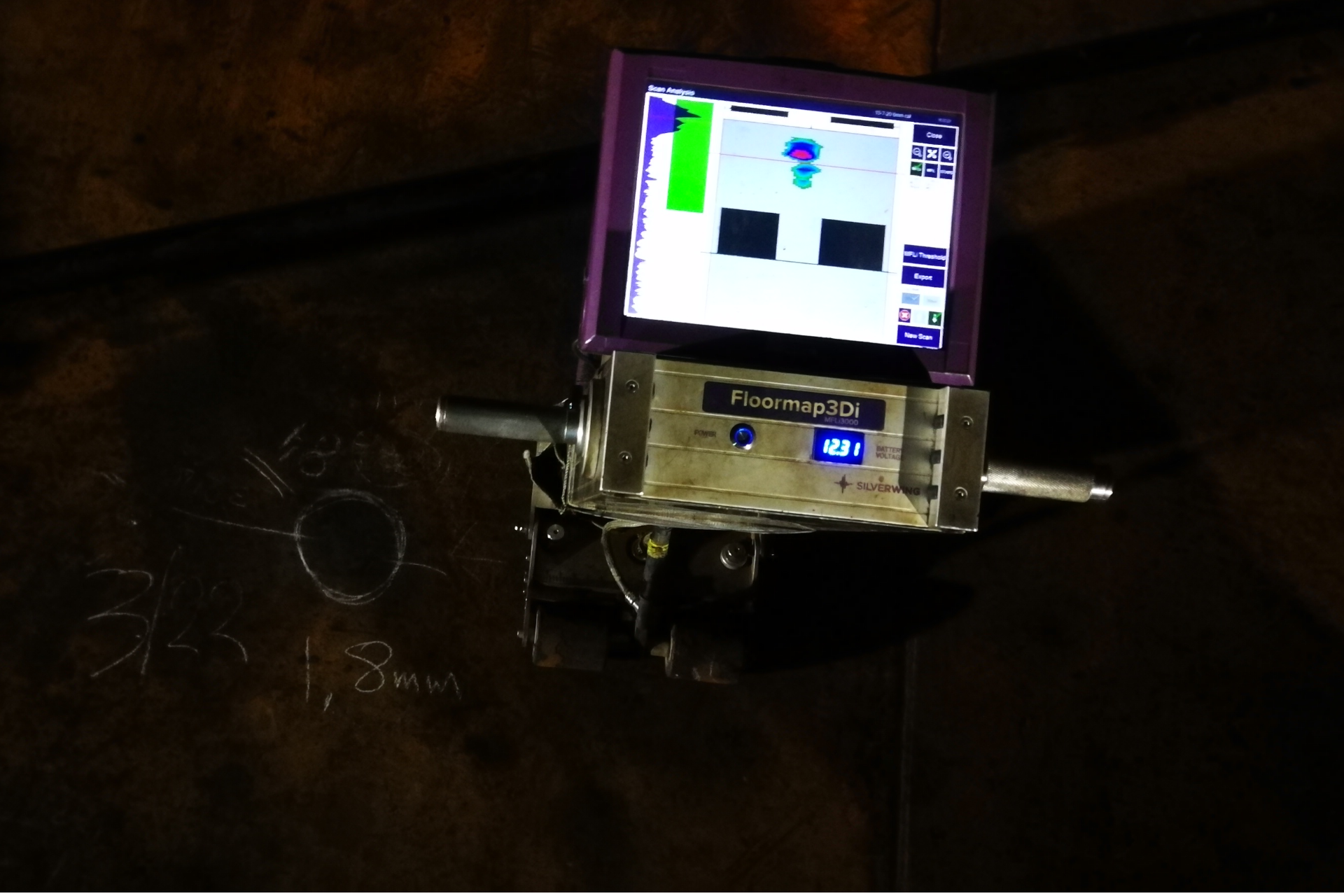

The basic principle is that a powerful magnet is used to magnetise the steel. At areas where there is corrosion or missing metal, the magnetic field “leaks” from the steel. In a MFL tool, a magnetic detector is placed between the poles of the magnet to detect the leakage field. Analysts interpret the chart recording of the leakage field to identify damaged areas and to estimate the amount of metal loss.

There are several advantages of MFL:

- One of the few methods used to inspect finned tubes

- Can be carried out with a single side access

- Can be used on all ferromagnetic materials

- Good sensitivity to pitting

- High-speed inspection

- MFL is a qualitative method. For accurate sizing, it must be combined with other NDT techniques.

- Ideal for detection of pitting corrosion. But can supersize lake-type corrosion and downsize pipe-type corrosion, thus distorting sizing accuracy.

Low ferromagnetic and ferromagnetic materials such as carbosteel have excellent compatibility with Magnetic Flux Leakage.

Newtron Magnetic Flux Leakage is commonly used for inspecting tank floors in the petrochemical industry, especially for detecting areas of isolated corrosion pitting in storage tank bottoms. Corrosion of the tank floor can lead to the loss of product and cause damage to the environment. Therefore, it is vital that tank floor inspections are carried out in order to prevent the occurrence of such problems.

International Organization for Standardization (ISO)

ISO 10893-3 Non-destructive testing of steel tubes — Part 3 automated full peripheral flux leakage testing of seamless and welded (except submerged arc-welded) ferromagnetic steel tubes for the detection of longitudinal and/or transverse imperfections (2011)

American Society for Testing and Materials (ASTM)

ASTM E570-20 Standard Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products

ASTM E709-21 Standard Guide for Magnetic Particle Testing

ASTM E1571-21 Standard Practice for Electromagnetic Examination of Ferromagnetic Steel Wire Rope

American Society of Mechanical Engineers (ASME)

ASME Boiler and Pressure Vessel Code, Section V

American Petroleum Institute (API)

API650 Welded Tanks for Oil Storage, Thirteenth Edition

API 653 – Aboveground Storage Tank Inspector

This information is a collection of references. While we have made every attempt to ensure that information on this site is updated, Newtron is not responsible for any errors or omissions, or for the results obtained from the use of this information. It is not guaranteed to be complete, correct, current, or up to date and may be changed without prior notice.