Non-Destructive Testing

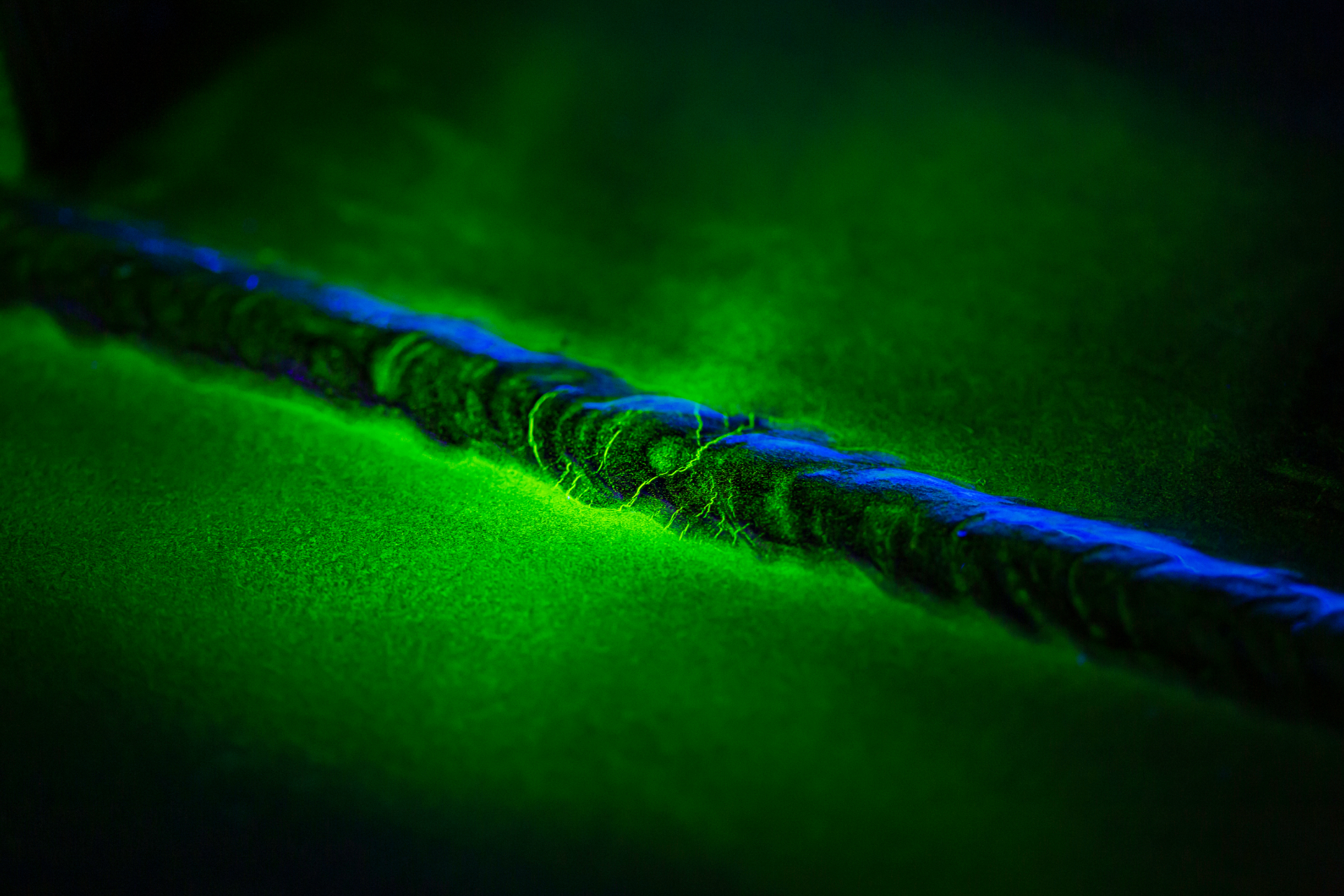

Non-Destructive Testing [NDT] refers to an array of testing methods used by inspectors in many industries to evaluate the properties of a single material, a construction component, a complex structure or even a system, for characteristic differences or defects and discontinuities without causing damage to the original part.

Inspectors use several methods in NDT for the collection of various types of data, each technique requiring its own kind of tools, training, and preparation. Some might allow for a complete volumetric inspection of an object, while others only allow for a surface inspection. In a similar way, some have varying degrees of success depending on the type of material they’re used on, while some others will only work on specific materials based on the material properties.

These include:

Depending on the reason an inspection is needed, one can claim that NDT methods are used in many industries worldwide. Especially, Visual Inspections take place in almost every workplace in some form or another.

However, there are specific industries where NDT is required and thus, these have formalised processes for its use, as codified by organisations like API and ASME.

These industries include:

Some of the most important types of NDT inspections concern assets like boilers and pressure vessels, which can be incredibly dangerous if not properly maintained. Because proper maintenance of these assets is crucial for the safety of those working nearby, most countries have laws requiring companies to adhere to specific inspection codes and standards when conducting inspections. These codes and standards typically require inspections to be conducted periodically and following specific guidelines. Here are the most commonly regarded organisations in the world for creating NDT codes and standards:

This information is a collection of references. While we have made every attempt to ensure that information on this site is updated, Newtron Technologies is not responsible for any errors or omissions, or for the results obtained from the use of this information. It is not guaranteed to be complete, correct, current, or up to date and may be changed without prior notice.