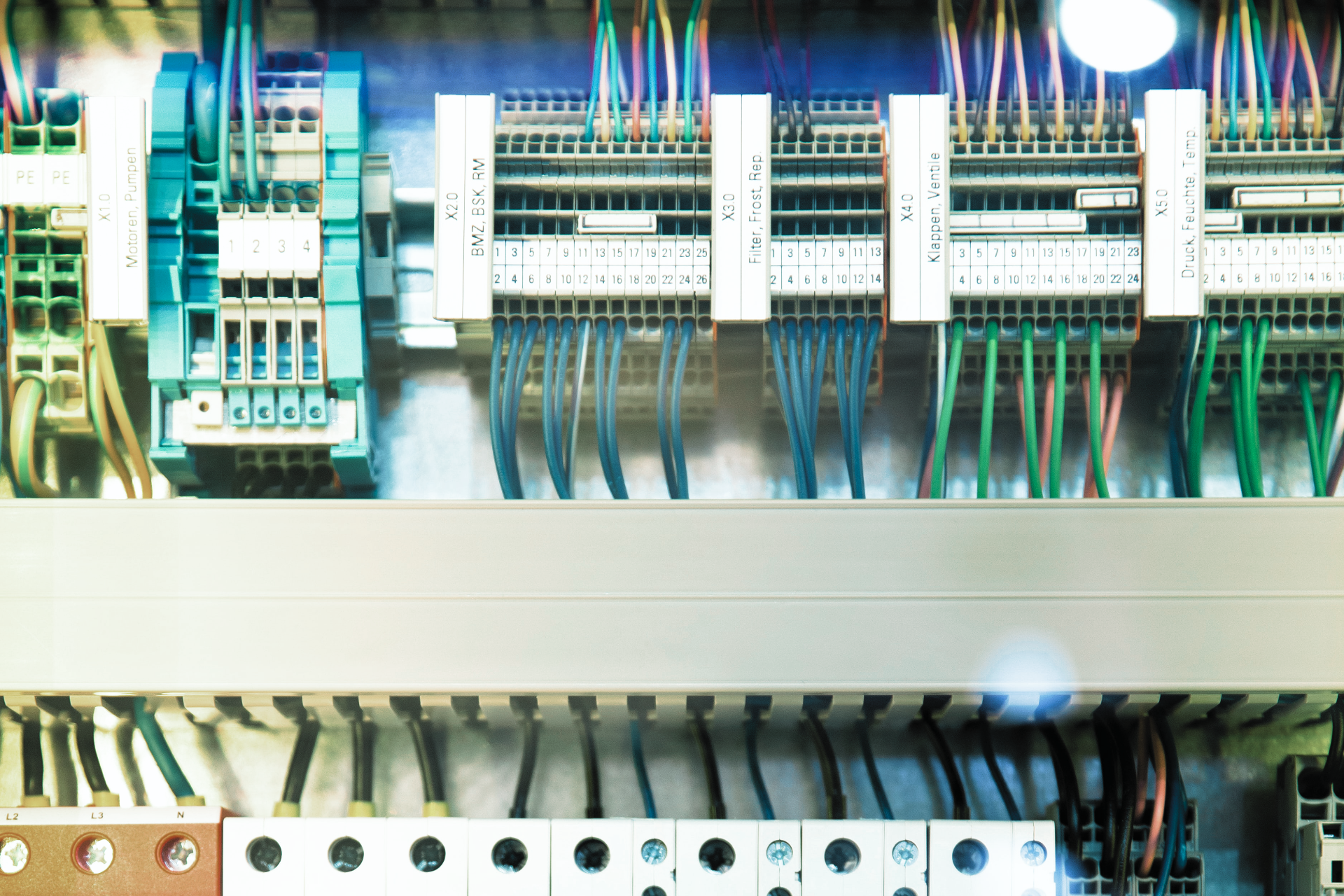

Electrical Equipment

Electrical Equipment testing and inspections are key to maintaining their safety, reliability, and technical efficiency and in extent, ensuring the reliable operation of your facilities for staff and visitors.

Furthermore, they detect any faults early, thus allowing for efficient management of potential breakdowns, enabling better planning of maintenance and repair programs and driving costs down by minimising out-of-budget repair incidents and reducing insurance premiums.

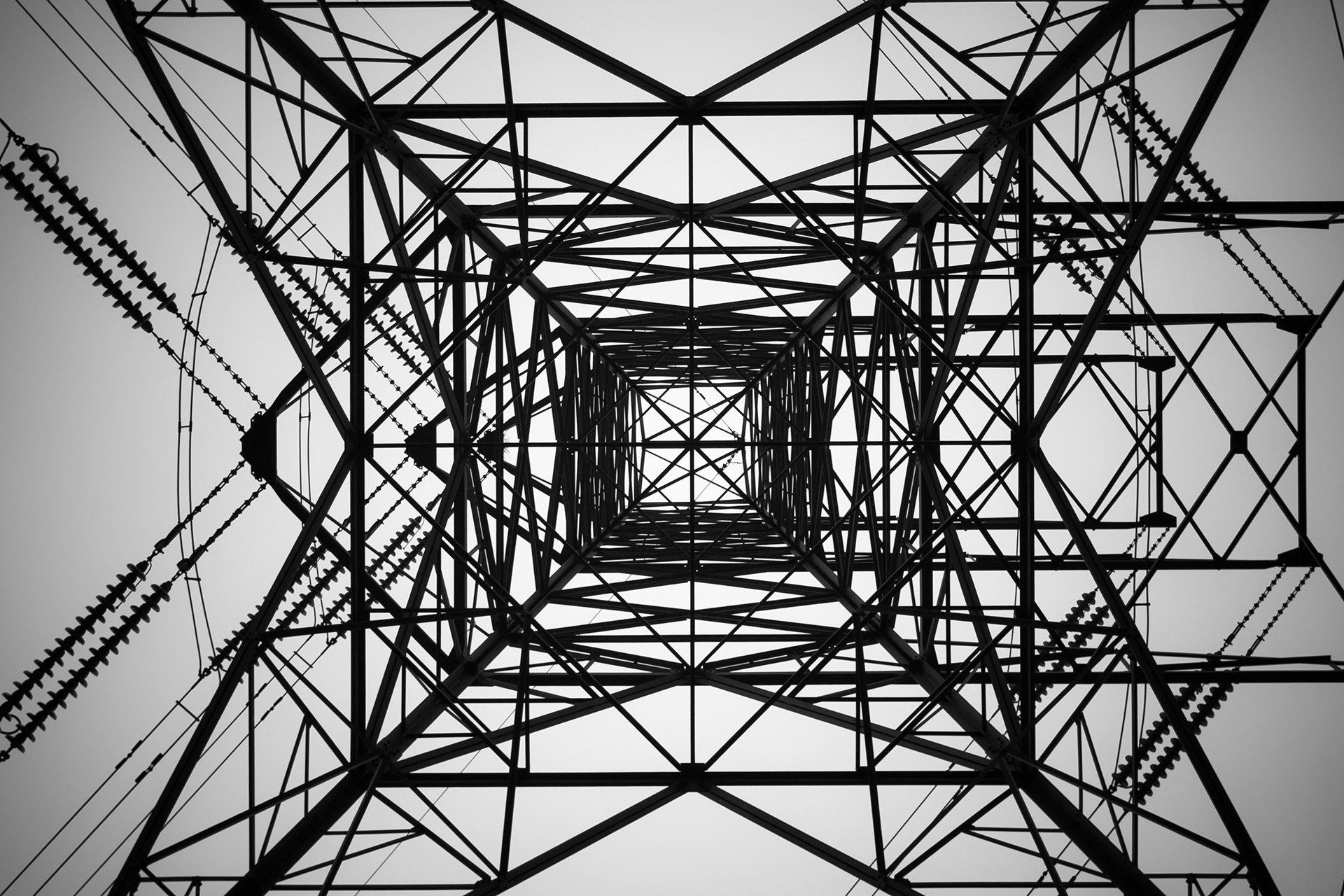

Newtron’s solutions, carried out by knowledgeable, certified inspectors, involve the testing and diagnosis, condition monitoring, as well as predictive and preventive maintenance for all types of electrical installations and equipment (low-, medium- and high-voltage), such as transformers, motors, generators, cables, earthed systems, to name but a few.

In detail our solutions include:

- Fixed electrical wiring inspection and testing

- Thermographic testing

- Electrical safety auditing

- Risk assessments of fixed electrical installations

- Drawings, tracing, labelling and schedules of electrical installations

- Assessment of the condition of HV equipment

- Overall Insulations analysis

- Emergency lighting inspection and test to BS 5266 standard

- Review of project engineering for electrical systems

- Electrical load analysis

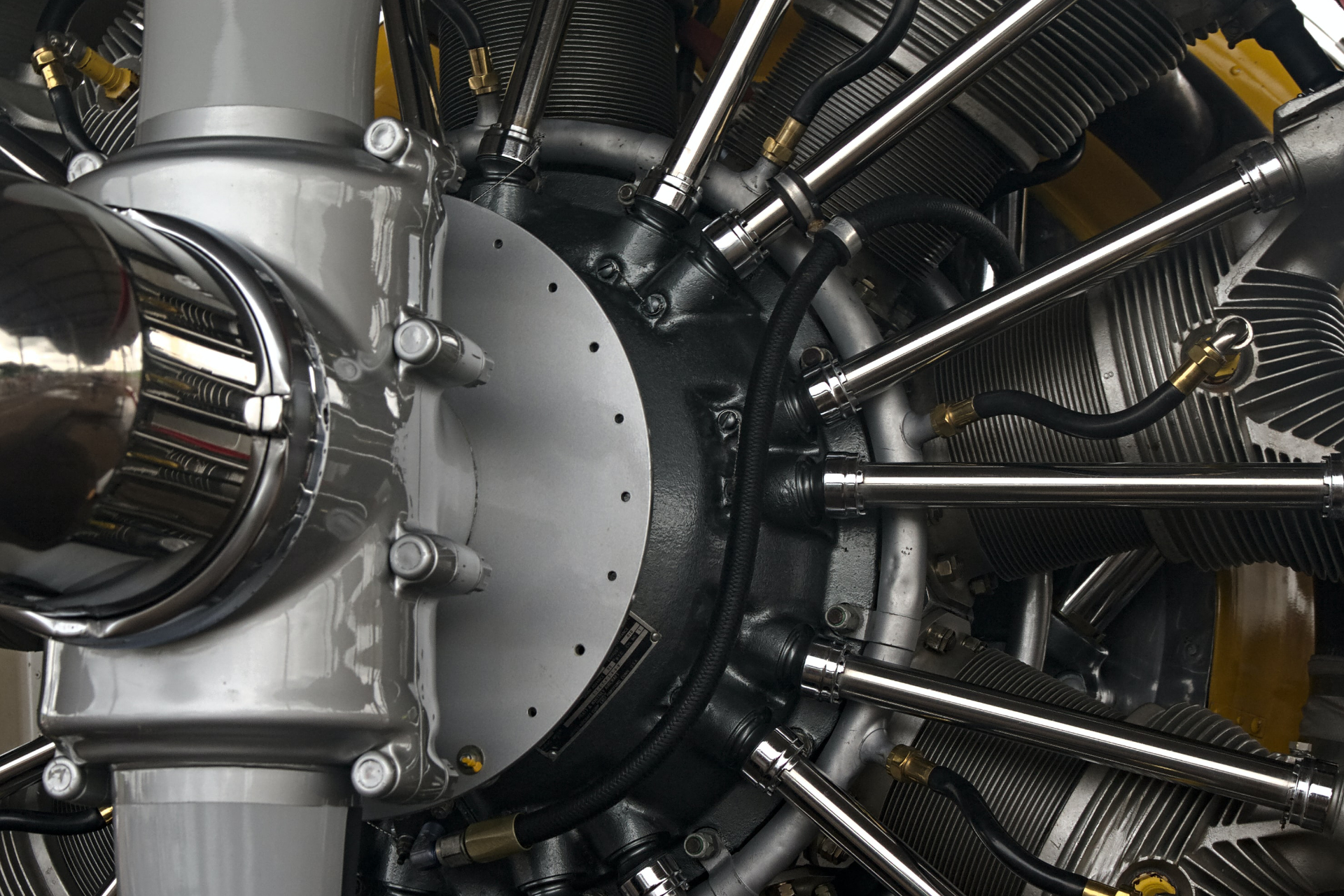

- Electrical safety assessments for plant and machinery

We have the experts and can offer solutions that assure the quality, cost-effectiveness, safety and operability of your electrical installation and equipment, as well as their compliance with local and international codes and standards.

Inspectors use safe and non-intrusive testing methods, such as Thermography, that allow them to detect failures in machines before they become unmanageable (weak spots, leaks, worn bearings, overheating and much more).

Electrical Equipment Testing applied technologies include:

- Visual Testing [VT]

- Thermography

- Vibration Analysis